Algatech: Functional food on astaxanthin horizon

This content item was originally published on www.foodnavigator.com, a William Reed online publication.

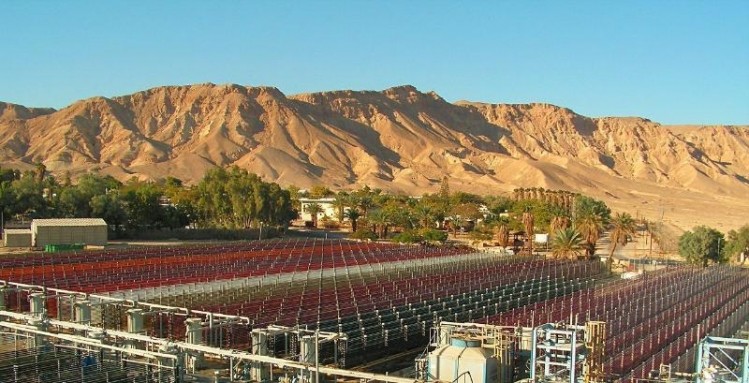

After a $20 million plant investment set to expand production capacity by over 100% is completed the firm will be better equipped to cut prices and meet demand for its algae products that is currently outstripping supply, the firm told us at its site in the Arava Desert in Israel.

Then it could move on to applying for approval as a novel food and beverage ingredient within the European Union, a safety go-ahead it already has in Japan and the US, said Efrat Kat, director of marketing and sales for the company.

The company's director, Hagai Stadler, also hinted that it would be announcing a new algae product at Geneva's VitaFoods expo in May that would be of a much higher concentration, potentially reaching 20%. It said the product would allow manufacturers the freedom to produce smaller capsules or add other ingredients within the supplement mix.

A novel food ingredient

Kat said the main problem for the company was supply, and it would hold off from releasing and promoting new applications until this was addressed.

"But we believe that within the next one or two years we will be in a position to actually promote and develop the delivery system for astaxanthin that will enable us and our customers to use astaxanthin as a functional food ingredient."

She said work remained on finding the right delivery system but its history in markets like Japan and the US would stand it in good stead to do this, and these markets would be the initial point of focus.

High Stress

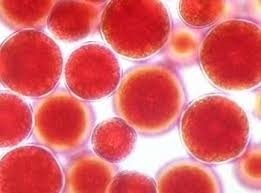

Pinpointed for its antioxidant potential, astaxanthin is the red pigment found in algae and aquatic animals that eat algae. This pigment is part of the algae's defence mechanism when it is exposed to too much sunlight, heat or starved of a food supply.

Algatech triggers the release of the carotenoid by exposing the microalgae variety Haematococcus pluvialis - which it says is the richest known natural source of astaxanthin - to sunlight stress causing the green algae to release astaxanthin and turn red in the process of defending itself against UV damage.

It said its way of inducing this naturally occurring process within a closed pipe circuit produces a quality of astaxanthin superior to its pond-produced or synthetic counterparts since it eliminates potential contamination. It said its AstaPure brand has on average a 98% astaxanthin purity, while the market average sits at about 80%.

"Mixing - for us that's really a red flag," Stadler said.

A (pricey) cloud of details

Stadler said that it was open about its process of producing and extracting astaxanthin since to reproduce these effects would depend on, "one big cloud of details".

"There are very few companies like this is the world - mainly because it's frustrating," he said.

The plant is located on the outskirts of a Jewish community called a Kibbutz, with many of the workers living within the commune. He said this setting was well suited to the nature of algae cultivation.

"It's like an intensive care unit," he said. "With the Kibbutz, if something happens there can be someone there in five minutes. Control is very important."

However, he said this process as well as the plant's current limited production capacity - the firm is sold out for 2014 and half of 2015 - meant Algatech's astaxanthin was expensive.

Outside of this he said the firm was committed to improving operational efficiency by reducing its water footprint and harnessing the desert sun energy with solar panels.

The firm recycles more than 70% of its water, while the water used in the later treatment stages which must be kept fresh, is sent to local date plantations. "When you go to Europe it's very difficult to explain how precious water is [in the desert]," he said.

He added that 85% of Israel's waste water goes to agriculture and that the company, like others in the area, was subject to a cap on the amount of water it can use.