Scientists and industry met for the 73rd International Congress and Annual Meeting of the Society for Medicinal Plant and Natural Product Research (GA) in Naples, Italy, from Sept. 1 to 3.

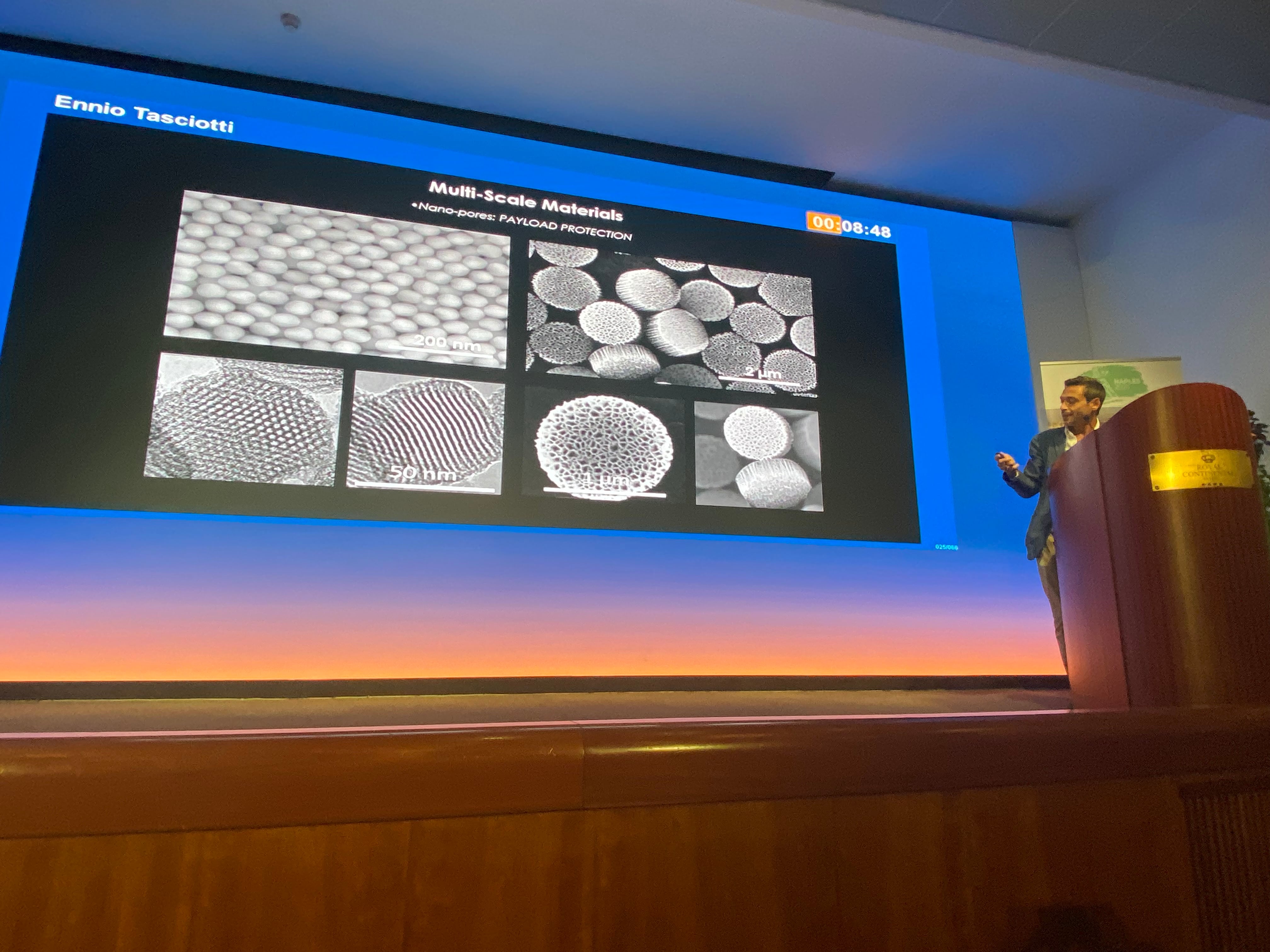

Providing a keynote presentation on new encapsulation techniques, Professor Ennio Tasciotti, director of human longevity program at the San Raffaele Scientific Institute for Research, Hospitalization and Healthcare (IRCCS), illustrated the applications of nano and micro formulations to boost therapeutic properties of plant-derived actives.

Once active ingredients enter the human body, they have to remain stable through multiple biological systems before release at the optimum time, he explained.

Tasciotti’s team has therefore developed a range of solutions to protect active ingredients within a range of applications—from vaccinations to ingestible liquid, pills or capsules.

He explained that when developing solutions for use within injectable drugs or vaccinations, the molecules need to be nanoscopic. When formulating ingredients for ingestion, the size constrainst are more relaxed, allowing for the use of microencapsulation and opening opportunities for innovation.

His team has created a menu of creative microencapsulation solutions to meet the needs of different ingredients. These are: mononuclear, multi-walled, multinuclear core, mixed polymer matrix, coated mixed multinuclear core, coated matrix particle, patchy microparticl, and double-compartment capsule.

“A mixed polymer matrix, for example, brings together many nano-particles congealed together and aggregated loosely so they are not very stable but in the right environment will open-up and release “like a drop bomb of active ingredient.”

He added: “The beauty is all of these can be modeled and programmed according to whatever release you want, whether its hours, days, weeks—we go all the way to months.”

His team has further developed a “multi-scale material” field of research since 2001 in which they are “creating objects within objects, like a Russian doll effect,” starting with molecules 50 nano meters in size.

“It takes time for these molecules to diffuse out, and this is good for sustained release, Tasciotti said. ”But if you put these inside the pores of a larger structure so you go from 50 nm to one or two microns, ghat gives another layer of control. You can develop very controlled synthetic ways to put a fixed number of cells within these structures.”

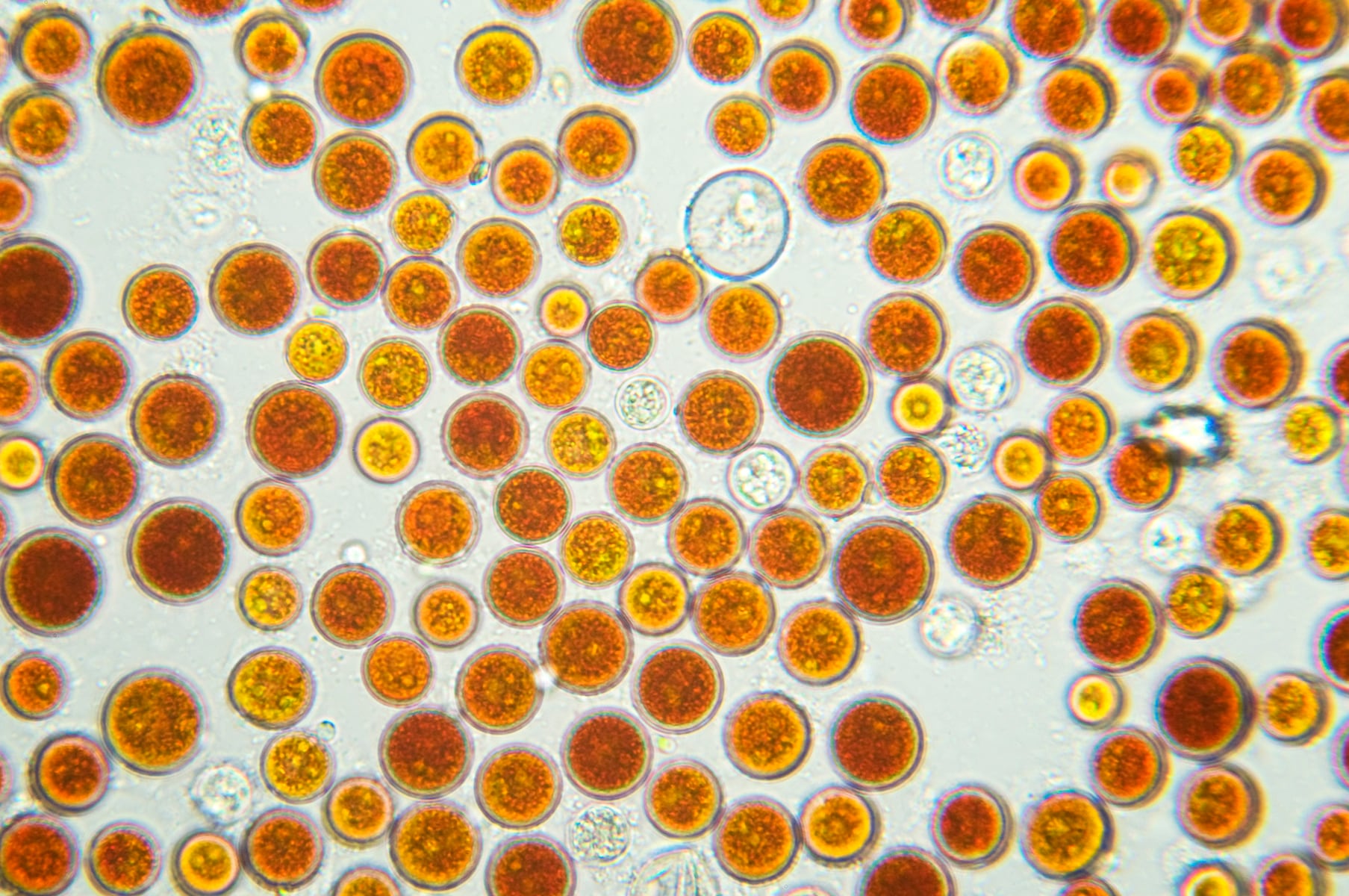

He further discussed the growing interest in plant-derived exosome-like nanoparticles (PDENs), also referred to as PELNs.

“Cells already make their own versions of nanoparticles, called exosomes or extracellular vesicles—the little structure that every cell has," he said.

“Plants also have exosomes. I believe these could be a beautiful alternative to some of the formulation issues because they regulate inflammation, they can cross talk between species so seem to be good for human biology.

PDENs have been found to modulate gene expression and immune responses. For example, grape-derived exosomes have been shown to regulate triglyceride levels, and ginger-derived exosomes reduce inflammation in colitis models.

Research has also concluded that, compared with synthetic nanoparticles and mammalian cell derived exosomes (MDEs), PELNs have lower toxicity and immunogenicity and possess excellent biocompatibility.

Some nutraceutical pioneers already using this method include Italian supplier Exolab and Spanish supplier PhNóva.

What’s more, Tasciotti said companies should find it ‘easy’ to patent protect plant exosomes innovations.

“There is not an issue with patenting plant exosomes because this is a technology so this allows you to protect your discovery,” he said.